Address

#10, K.E.B Road, Newpet

Anekal, Bangalore -562106

Work Hours

Monday to Saturday: 9AM - 6PM

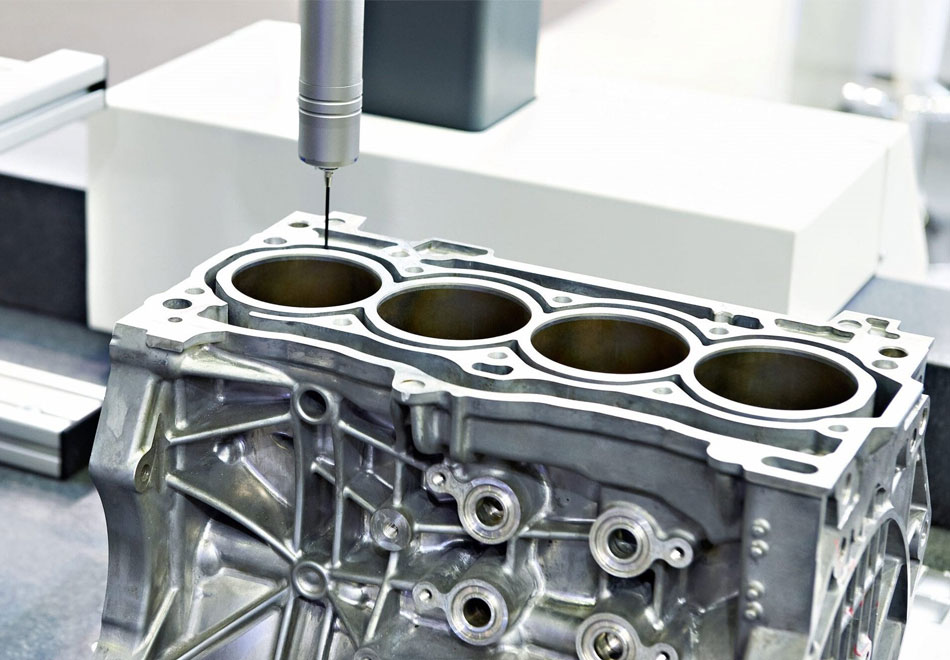

Coordinate Measuring Machine (CMM) inspection is a highly accurate method used to measure the 3D geometry of physical parts and components. By using a precision-controlled probe—either touch-trigger, scanning, or non-contact—a CMM collects detailed dimensional data to verify that parts conform to engineering drawings, CAD models, and tolerance specifications.

CMM inspection plays a critical role in quality control, ensuring that complex components—especially those used in aerospace, automotive, defense, and medical device industries—meet exact design requirements. Whether you’re validating prototypes or inspecting production batches, CMMs offer unmatched precision, repeatability, and traceability for every measurement task.

CMM (Coordinate Measuring Machine) inspection plays a vital role in ensuring the dimensional accuracy and performance of precision-engineered components. Here’s where and why CMM inspection is essential:

CMM inspection ensures that aircraft parts meet extremely tight tolerances and aerospace quality standards, reducing risk and ensuring flight safety.

Used to inspect engine blocks, gears, chassis components, and more—CMMs help maintain part consistency and compliance across high-volume automotive production lines.

CMMs validate die and mold profiles to ensure dimensional accuracy before production, reducing downstream defects and tool rework.

In the medical field, precision is critical. CMM inspection helps manufacturers meet stringent FDA and ISO requirements by verifying intricate medical components.

CMMs are widely used in reverse engineering to create accurate 3D models from physical components, especially when original CAD data is unavailable.

FAI verifies that initial production parts match design specifications, preventing costly errors in full-scale manufacturing. CMMs offer detailed reporting for quality assurance.

We provide a full range of CMM inspection services designed to meet critical quality and dimensional control requirements across industries. Each service ensures precision, compliance, and confidence in your production process.

We perform high-accuracy 3D measurements to confirm that part dimensions align with technical drawings and manufacturing specifications.

We validate features such as flatness, concentricity, parallelism, and true position according to GD&T standards to ensure design integrity.

We compare measured data directly to 3D CAD models using advanced software to identify any deviation and ensure product conformity.

We analyze surface profiles, edges, and curves to verify critical geometry on parts such as blades, gears, and molded components.

We offer independent, NABL-accredited inspection reports for supplier validation, compliance checks, and contractual quality verification.

We provide thorough inspection for production batches or random samples to monitor consistency and detect any manufacturing variances.

Experience the highest level of accuracy with the Carl Zeiss PRISMO CMM featuring an integrated rotary table—engineered for ultra-precise 3D measurements of gears, blades, and rotational components. With a length measurement error of less than 1.2 µm, this high-performance CMM inspection system ensures exceptional results in aerospace, automotive, and precision engineering applications. Ideal for rotational symmetry inspection, gear measurement, and blade profile analysis, the ZEISS PRISMO accelerates your quality control process while guaranteeing full compliance with global standards.

At Sirige Quality Laboratory, we offer expert CMM inspection services using advanced Coordinate Measuring Machines to deliver precise, reliable, and traceable dimensional verification. Ideal for parts with tight tolerances, complex geometries, and critical quality requirements, our CMM solutions ensure total compliance with industry standards. Whether for aerospace, automotive, tooling, or manufacturing, we provide fast, data-driven insights that support flawless production and high-performance results.

The HEXAGON Global Status 7107 CMM delivers superior accuracy for critical part measurements using a touch-trigger probe and cutting-edge metrology software. Designed to handle complex geometries and tight tolerance requirements, this CMM is ideal for industries like aerospace, automotive, and precision engineering. Whether you’re verifying prototypes or inspecting production parts, the Global Status 7107 ensures consistent, reliable results that support your most demanding quality control and dimensional analysis needs.