Address

#10, K.E.B Road, Newpet

Anekal, Bangalore -562106

Work Hours

Monday to Saturday: 9AM - 6PM

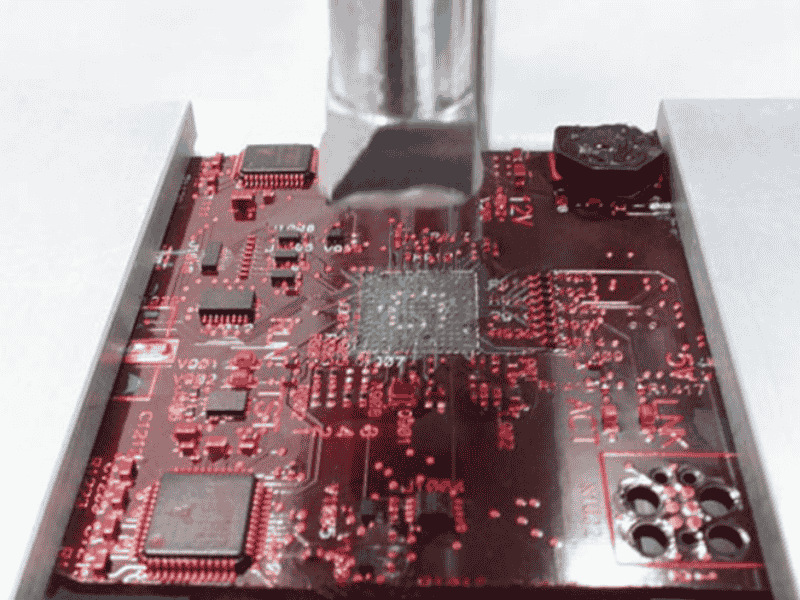

Hey there! Have you ever thought about what makes your favorite gadgets—like your smartphone, laptop, or even your gaming console—work so well? We often take these devices for granted, but behind the scenes, a lot of hard work goes into making sure they’re safe, reliable, and top-notch. One of the cool ways manufacturers do this is through something called Dye and Pry analysis. Let’s break it down together!

So, what exactly is Dye and Pry analysis? Well, think of it like a detective story for materials. When companies create electronic products, they use all sorts of materials—like metals and plastics. But how do they know these materials are good enough?

Dye analysis is like a magic trick! Manufacturers use a special dye that can reveal hidden problems in the materials. Imagine painting a wall—if the paint goes on smoothly, that’s great! But if it starts to bubble or peel, you know there’s something wrong. In the same way, when the dye test is carried out on a material, it should spread evenly. If it doesn’t, that’s a red flag! It shows that the material might have defects that could lead to issues later on.

Now, let’s talk about Pry analysis (which stands for Physical Review of Yield). This is a bit more technical but still super interesting. Basically, Pry analysis looks at how materials hold up under pressure. Think of it like a superhero test! When devices are put through heat, moisture, and even a little rough handling, they need to stand strong. Pry analysis helps manufacturers see if the materials will crack or break when things get tough.

You might be wondering, “Why is all this testing so important?” Great question! Here are a few reasons:

Let’s take a quick look at how this testing process unfolds:

Dye and Pry analysis might sound technical, but it’s all about making sure we have safe and reliable electronics that we can count on. It’s like giving our devices a thorough health checkup before they hit the market.