Address

#10, K.E.B Road, Newpet

Anekal, Bangalore -562106

Work Hours

Monday to Saturday: 9AM - 6PM

Have you ever asked yourself where we get the measurements that are used in our daily life from? At some point in our lives we use measurement from the amount of weight that groceries, the amount of medications, or even the size dimensions of a manufactured part. This is where measurement traceability comes into the picture. In other words, measurement traceability is the key to warrant that what we obtain is indeed precise and credible. Especially in industries in which the manufacturing itself is a cause of risk or for healthcare for example, one small mistake can cost greatly. In this blog post, we’ll discuss the concept of traceability when it comes to measurement and some best practices that go into making measurement work.

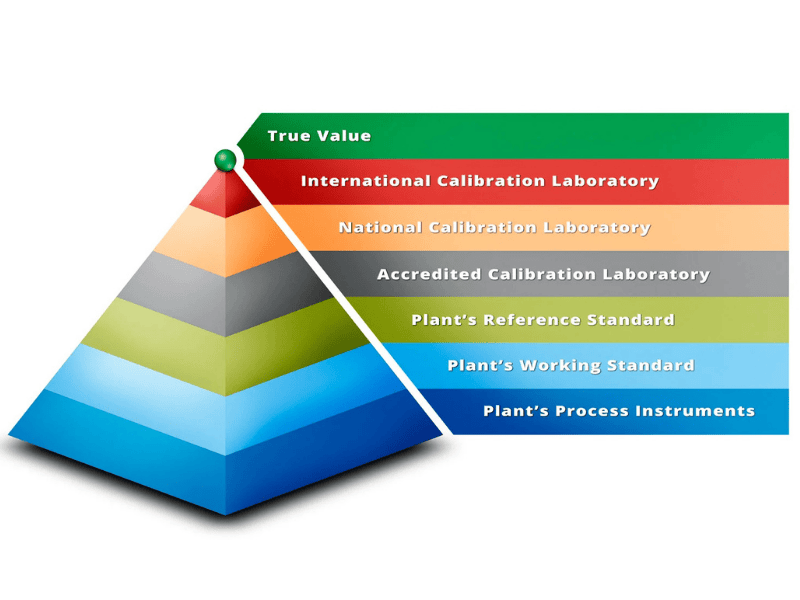

When Sigmund’s measurement results to a particular process are related to the national or international standards, this is known as measurement traceability. It works kind of like a chain; in this case, each link is actually making a comparison to a standard that has been accepted as true.

There are three main parts to measurement traceability:

Calibration: From this it means constant calibration of measuring instruments to set as to get correct measurements.

Standards: Appending accredited standards (as with ISO /IS ) that describe in greater detail how such measurements need to be conducted.

Documentation: Assuring all records of measurements conducted and calibration activities and processes integrity.

The traceability chain has relevance because it provides confidence in the measurements obtained. The chain should be unbroken and end in National or International standard. Every link must be clear and supported so you can and say that you indeed have the right measurement. This is very important in the issue of quality and compliance in any form of production in various sectors.

To the next level of output, certain validation and measurement must be achieved to make them reliable so there can be accurate measurements for result-oriented assessment.

Measurement traceability refers to a procedure that assists in guaranteeing that your measurement is accurate. Without it, you are likely to be working with the wrong data, which will cost you a lot of money in the long run.

Most companies across many industries have regulatory standards that demand the ability to track their products. Besides being an effective way of ensuring that you are compliant, the implementation of the guidelines improves your credibility. This means that customers are more likely to trust firms who observe measurement seriously.

In sectors such as manufacturing and health care the issue of traceability is relevant to determining the quality and safety of the final product. Good measurements enable organizations to avoid production of defective products and products that have not met safety requirements.

Your customers are also more likely to trust your products and services if only they could be assured that your business has a highly standardized measurement system. Such trust can be taken to mean a customer decision to patronize the retailer again in the future and recommend the business to others.

First, it will be helpful to describe what traceability looks like to your organization. Brief your subordinates as to ensure that everyone is in agreement with what the various members aimed and expected to do.

It is highly recommended to apply National and International standards that are existing in the certain field of industry. These standards form a basis or framework within which your measurements are taken from. So, don’t hesitate to spend more time selecting the most suitable options.

Develop a practice of how often you should conduct the measuring instruments’ check up and calibrations. Make sure you document these activities and perhaps write them in a log book so that you can be able to show your supervisor that you are keeping things accurate.

Document everything! This equates to retention of records that include calibration certificates, measurement logs, or any audit performed. Therefore, effective documentation implement consolidation or superposition of information are important for traceability.

Your team also has to be clear why traceability is important and how to do it properly. Since measurement standards and practices change with time, it may be beneficial to hold training sessions at specified intervals to ensure that everyone is up-to-date.

It may be advisable to use software when taking measurements, and keep records of the results. With the help of automation, you can minimize the mistakes which occur in your work and your processes will be faster.

Everything related to traceability should have the respecting standards of the company and you should establish an internal audit system that checks if everything is in compliance. This can include prevailing any signs of infections before they become huge concerns to the body.

One manufacturing firm got to address the issues of traceability in theirProduction system. They made a practice of calibrating their instruments on a routine basis and kept a record of activities that were carried out. Therefore they were able to cut down the number of defects by a third and end up cutting down on their costs while at same time making customers happy.

A hospital agreed with the medical reasoning for having traceability for the medical equipment. Thus, by properly implementing traceability, measurement was accurate and regulatory compliance was assured. This translated into improved observation of patient rights resulting in improved safety and enhanced community trust.

Barriers that may be encountered by many organizations when implementing traceability include among others; shortage of capital, and organizational resistance to change. Such barriers can really confound any efforts to build effective practices.

Still, to achieve these objectives, the primary emphasis should be placed on explaining to your staff the value of traceability. It can also help in reducing the complexity of the processes which often makes most people feel uncomfortable with their implementation.

In an ever embracing environment where accuracy is the key to success, measurement traceability is the key to that success. Applying recommendations in measurements, you will come across reliable and best practice results. Consider the current practices, or rather, is there anything you could potentially change? Adopting traceability will not only improve your business hence operations but also improve your relationship with your customers.