ZEISS PRISMO & HEXAGON CMM

At Sirige Quality Laboratory, we specialize in Coordinate Measuring Machine (CMM) inspection services to deliver the highest level of dimensional accuracy, consistency, and quality assurance. With industries moving toward micron-level precision manufacturing, the need for advanced CMM inspection has never been greater. Our laboratory is equipped with world-class CMMs from ZEISS and HEXAGON, ensuring our clients receive reliable and traceable measurement results that meet international standards.

ZEISS PRISMO with Rotary Table – Unmatched Precision

The ZEISS PRISMO is a benchmark in the world of precision measurement and high-speed scanning. Trusted globally, this CMM ensures that even the most complex parts are inspected with exceptional accuracy.

- Micron-level accuracy: Delivers a length measurement error of less than 1.2 μm, making it ideal for industries where precision is non-negotiable.

- Rotary table advantage: Designed for efficient measurement of blades, gears, turbine components, and rotationally symmetric parts.

- High-speed scanning: Reduces inspection cycle time without compromising accuracy.

- Industry application: Widely used in aerospace, automotive, defense, medical devices, and heavy engineering, where tolerance requirements are extremely tight.

By combining rotary technology with the legendary ZEISS precision, we ensure fast, efficient, and reliable inspection of critical components.

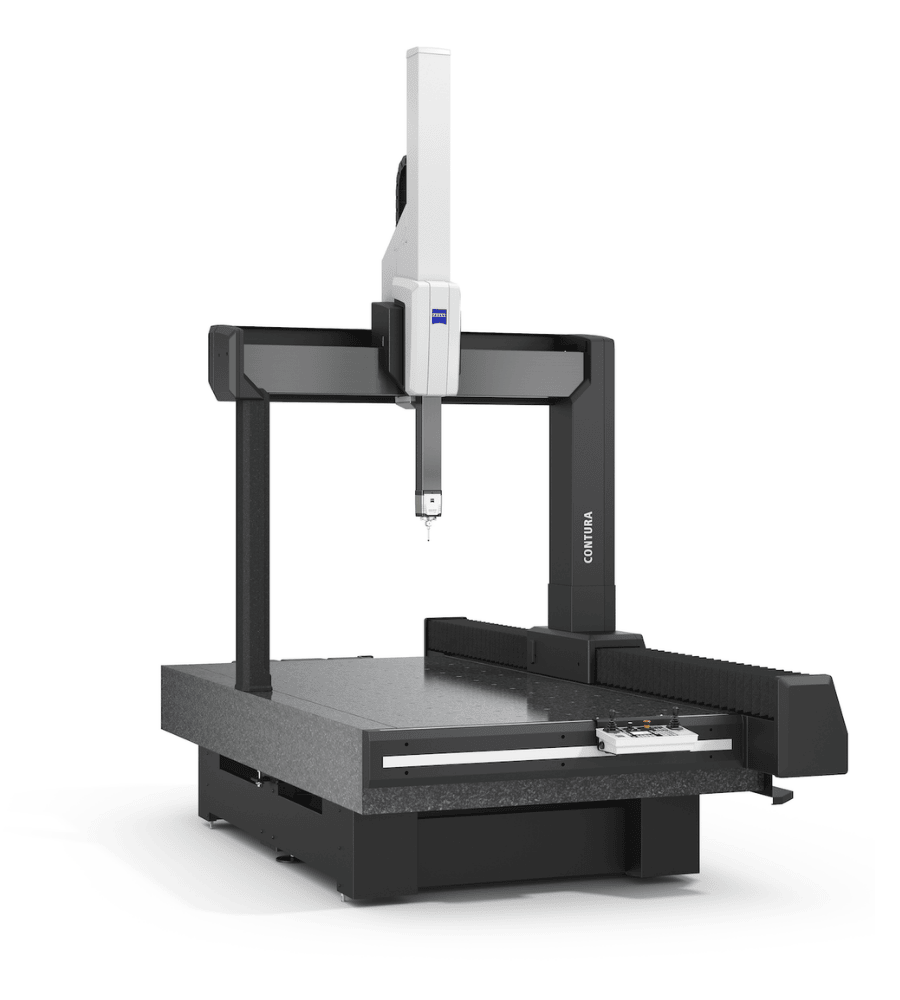

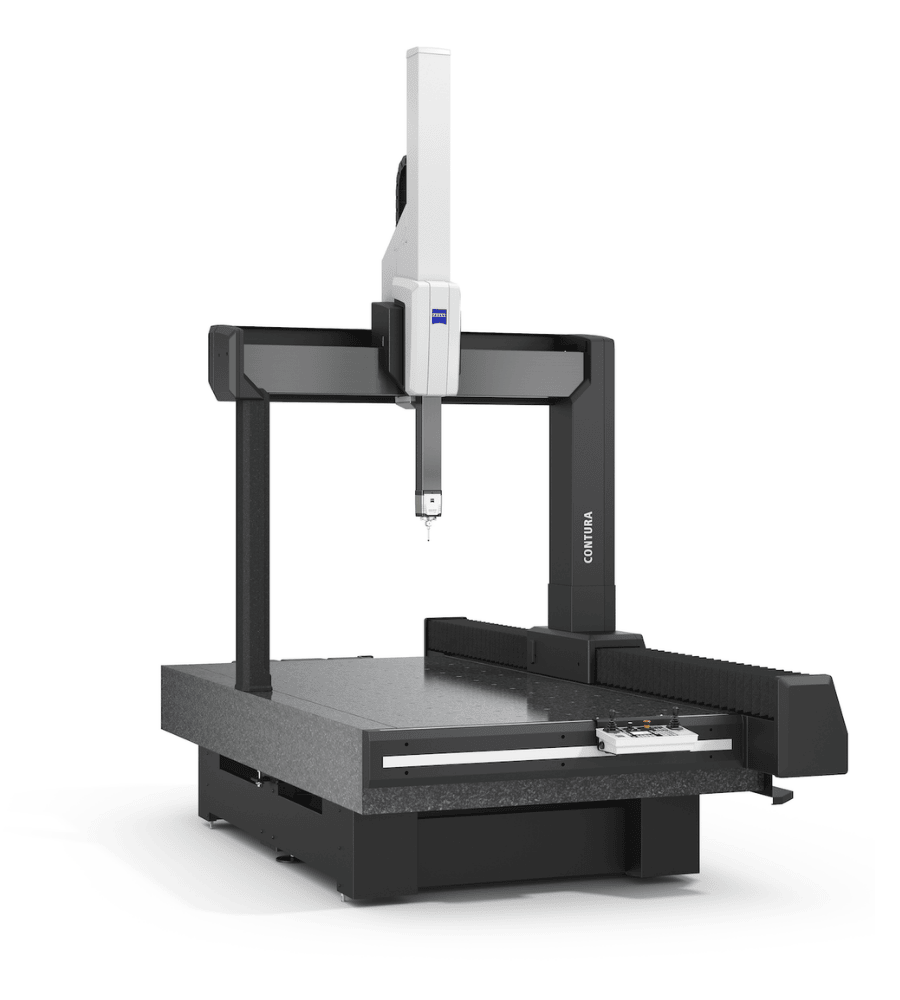

HEXAGON CMM – Global Status 7107 for Complex Geometries

The Global Status 7107 from HEXAGON METROLOGY is another cornerstone of our inspection capabilities. As manufacturing continues to evolve, with components becoming smaller, more complex, and more precise, this machine provides the perfect solution.

- Touch-trigger probe: Ensures accurate probing of intricate surfaces and complex geometries.

- Advanced software integration: Delivers powerful analysis, reporting, and 3D inspection capabilities.

- High tolerance inspection: Perfect for components that demand strict dimensional control and repeatability.

- Versatility: Suitable for aerospace, automotive, electronics, tooling, and high-precision manufacturing applications.

This technology enables us to handle sophisticated measurement tasks, ensuring that every part we inspect meets design intent and international quality standards.

Benefits of Our CMM Inspection Services

- State-of-the-art CMM equipment – ZEISS PRISMO and HEXAGON Global Status 7107.

- Expert technicians and metrology specialists with years of experience.

- Traceable measurement results complying with ISO and NABL standards.

- Improved quality assurance for critical parts and assemblies.

- Reduced rejection rates and cost savings by detecting dimensional deviations early.

Our CMM inspection services are not just about measurement; they are about delivering confidence in your manufacturing process and ensuring every part performs as expected.