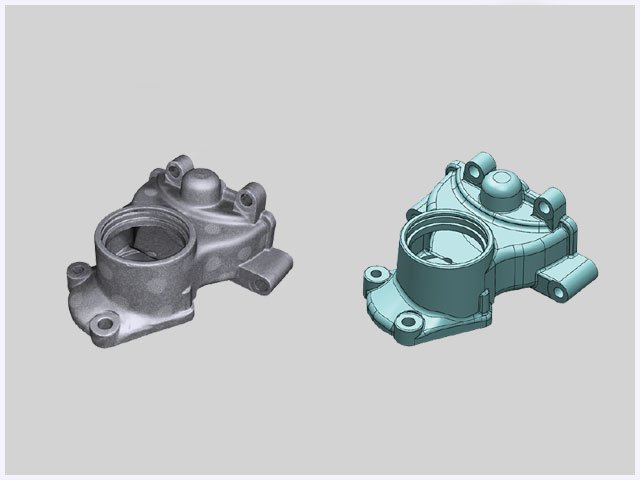

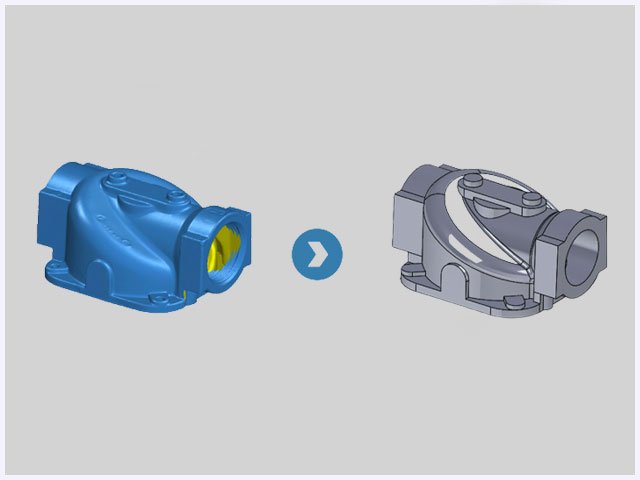

At Sirige Quality Laboratory, our Reverse Engineering Services help you recreate accurate 3D CAD models and STL data directly from physical parts — ideal for inspection, design modification, or reproduction.

Reverse Engineering, also known as backward engineering, is the process of reconstructing an existing product to understand its structure, functionality, and design intent. Through detailed analysis, we extract precise digital data from your product and convert it into a high-quality 3D model ready for further use in manufacturing or design.

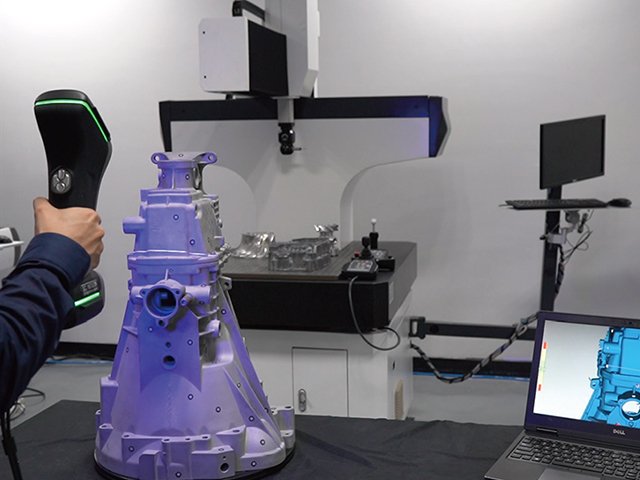

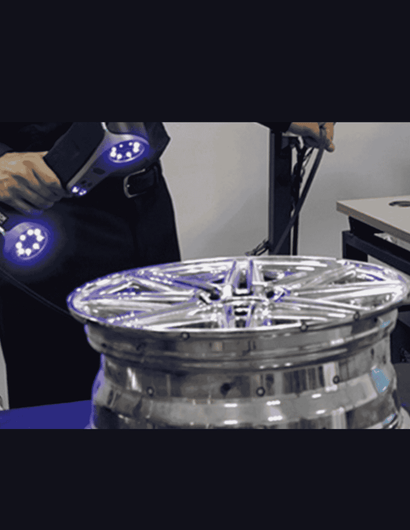

Using our KSCAN–MAGIC Composite 3D Scanner, we capture every minute detail with infrared and blue laser technology, offering five working modes and an integrated Photogrammetry System. This enables accurate scanning of components ranging from a few centimeters to several meters in size.

We also utilize our Carl Zeiss Prismo CMM with a rotary table and non-contact VMS system to ensure precision and reliability throughout the process. Our setup supports 3D inspection, gear reverse engineering (spur and helical profiles), and analysis of prismatic and freeform components.