Imagine you’re trying to bake a cake, and you need to measure the ingredients perfectly. If your measuring cups are off by a little bit, your cake might not turn out right. Just like baking, in many industries, measuring things accurately is super important, and that’s where dimension calibration comes in.

In this article, we’ll talk about how to achieve perfect accuracy with dimension calibration, and how understanding “uncertainty” helps you get even better results. It’s easier than you think!

What is Dimension Calibration?

Okay, let’s start with the basics. Dimension calibration is a way of making sure that the tools you use to measure things are showing the right numbers. Think of it like checking if your measuring cup is actually holding 1 cup of flour. You need to make sure your tools are giving you the correct measurements every time so your work is spot on.

In simple words: Dimension calibration makes sure that the ruler, caliper, or machine you are using is measuring things correctly. Whether you’re measuring the length of a pencil, the width of a door, or the thickness of a piece of metal, everything needs to be measured accurately to get the right results.

Why Does Dimension Calibration Matter?

If your measurements are even a tiny bit wrong, the results can be messed up. Imagine you’re building a model car and the wheels are too big for the body. That wouldn’t work! Here’s how dimension calibration helps:

- Correct measurements = perfect products: If your tools are calibrated right, you can be sure your product will be perfect.

- Avoiding mistakes: Without proper calibration, even small mistakes can turn into big problems.

- Quality matters: For companies, calibration makes sure products are made right and follow strict rules and standards like NABL and ISO 17025.

What’s Uncertainty and Why Does It Matter?

Now, let’s talk about uncertainty. Wait, what’s that? Don’t worry, it’s not as complicated as it sounds!

Uncertainty is simply how much we trust the measurements from our tools. Imagine you’re measuring the length of a pencil with a ruler, but the ruler might have small imperfections, like tiny scratches or bends. The measurement may not be perfect every time, but you can still know how much it might vary. This uncertainty tells you how sure you are about your measurement.

For example:

- If your ruler says the pencil is 12 cm, but you’re not 100% sure it’s exactly that, the uncertainty tells you how much it could be more or less than 12 cm. It helps you understand how accurate your measurement is.

So, achieving perfect accuracy isn’t just about measuring well; it’s about understanding the uncertainty in your tools to make sure the results are as good as possible!

Tools Used for Achieving Accuracy in Dimension Calibration

To get the most accurate measurements, you need to use the right tools. Here are some common tools that help in dimension calibration:

- CMM Machines (Coordinate Measuring Machines): These machines are used for super-accurate measurements, especially when parts are complex.

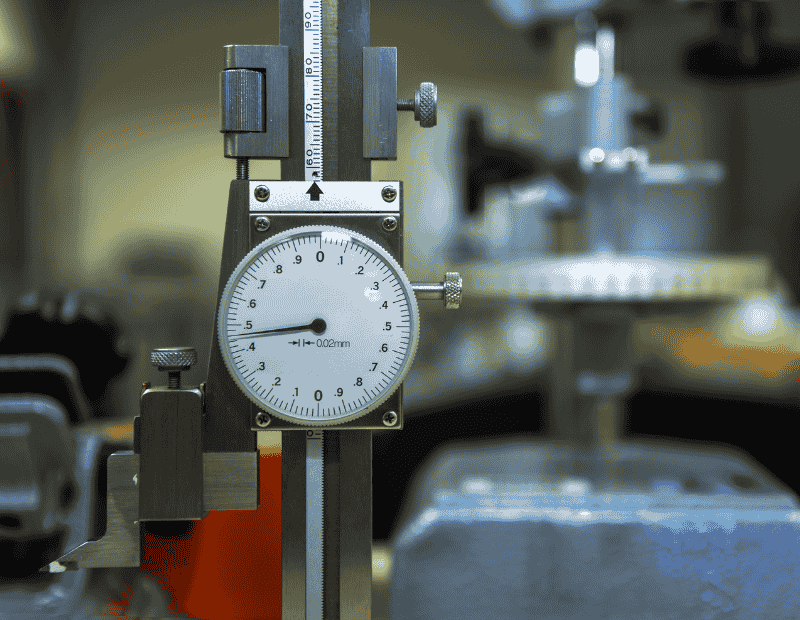

- Calipers: Handy for measuring thickness or the distance between two points.

- Micrometers: Used to measure tiny objects with very high accuracy.

- Gauge Blocks: These are used to check if the tools are giving you the right measurements.

And guess what? 3D scanners are also used these days to measure things faster and even more accurately!

How to Achieve Perfect Accuracy in Dimension Calibration?

Here’s a simple, step-by-step guide to help you calibrate your tools and reduce uncertainty for more accurate measurements.

Step 1: Pick the Right Tool

Make sure the tool you choose is the best for the job. For example, if you need to measure a tiny screw, use a micrometer. If you need to measure something larger, like a metal sheet, you might use a caliper or CMM machine.

Step 2: Prepare the Tools

Before you start, check that your tools are clean and not broken. If there are any dust or scratches on them, the measurements might be off. Make sure the place where you’re working is clean, and there aren’t any factors like temperature or humidity that could affect your measurements.

Step 3: Perform Calibration

Now, use your known reference (like a gauge block) to check if your tool gives the correct reading. This will help you see how accurate your tool is. Remember, uncertainty will show you how much the tool’s measurement can vary.

Step 4: Record Your Data

It’s important to write down the calibration results. This way, you can keep track of your tools and know when it’s time to recalibrate them.

Step 5: Double-Check Your Work

Do a final check to make sure everything is correct. The more careful you are, the better your results will be!

Common Problems in Dimension Calibration and How to Fix Them

Sometimes, things might not go as planned. Here are a couple of common issues you might face:

- Tool wear: Tools can get damaged over time, so it’s important to check them often. Regular cleaning and proper storage can help prevent this.

- Uncertainty: Uncertainty happens when your tools aren’t perfect, but it can be reduced by choosing high-quality tools and keeping them well-maintained.

Tip: Regularly clean and check your tools to make sure they are always in good shape and measuring correctly!

Best Practices for Perfect Accuracy in Dimension Calibration

If you want your tools to always be accurate, follow these practices:

- Calibration intervals: It’s important to check your tools at regular intervals (like every few months) to make sure they are still accurate.

- Maintenance: Regularly clean and fix your tools so they don’t wear out.

- Training: Make sure everyone using the tools knows how to properly calibrate them and understand the uncertainty involved in measurements.

Conclusion

Dimension calibration helps you achieve perfect accuracy in your measurements and reduce uncertainty. By following the steps above, you can make sure your tools are always ready to give you the right results, whether you’re measuring a tiny screw or a big metal plate. Accurate measurements are the key to making sure everything works as it should, from products to safety equipment.

Call to Action (CTA)

Ready to achieve perfect accuracy? Quality Laboratory offers professional calibration services and high-quality measuring tools like Precision Granite Plates, 3D Scanners, and more. Visit our website today to check out our services and get the best tools for your work!

🔗 Explore our services at Quality Laboratory!